Moghaghani niches, construction of niches in Tehran

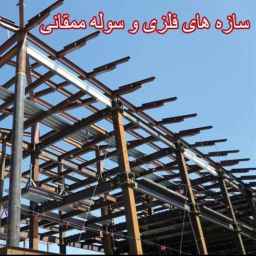

Shelving is a process in which large metal structures called sheds are built. These structures are widely used in various industries such as agriculture, industrial, warehousing and sports due to their high construction speed, flexibility in design and resistance to different weather conditions. Sheds are usually single-story and consist of prefabricated metal parts that are assembled on site. Sheds are made in different sizes and shapes and can be used for various purposes including production workshops, warehouses, sports halls and even exhibitions.

Types of industrial niches based on weight

Light shed: Light sheds are often used in industrial structures, which are usually two-dimensional and three-dimensional truss type. Light-weight holsters are more versatile than heavy-duty holsters and can usually be used anywhere. This type of structure is usually used in cold stores and industrial cattle farms. Light sheds are also called truss style sheds. Since these structures are designed with new engineering methods, they are made of square profile (ST37) and have high endurance. In this structure, the consumption of steel metal is reduced and for this reason it has a lower price.

Heavy shed: Heavy shed is divided into two categories, concrete and metal, and the execution time of metal shed is faster than concrete. Because in the concrete type, it takes about a few days to prepare the concrete. But in its metal type, after the foundation of the structure is prepared, the columns and roof rafters, etc., can be mounted on the foundation. But in terms of price, the metal shed is more expensive because it is made of steel, which is more expensive than concrete in the current market of Iran. For this reason, most people go for a concrete shed, which uses sheet beam pieces for high resistance to increase endurance.

The differences of lightweight and heavy

The light shed is made of pipe profiles, and for this reason, their weight is less than other methods. It is not low against heavy shed resistance. Of course, light sheds are built with truss methods. But the disadvantages of light sheds are more related to the price of their construction in specific and limited dimensions. In addition, sometimes the use of light and resistant materials can cause financial losses for the employer.

Sheds are metal structures with various applications in industries, agriculture, etc. These structures have been greatly appreciated due to their advantages such as high strength, reasonable price, high construction speed and diversity in dimensions and shapes. Sheds are designed and built in different types, including light, heavy, arched, single-span, multi-span, etc., each of which has its own use. Choosing the right type of shed depends on various factors such as required dimensions, type of use, loading, weather conditions of the region and budget. In this article, we tried to make a permanent shed in Tabriz, to discuss the issue of sheds in general. and get to know its types.