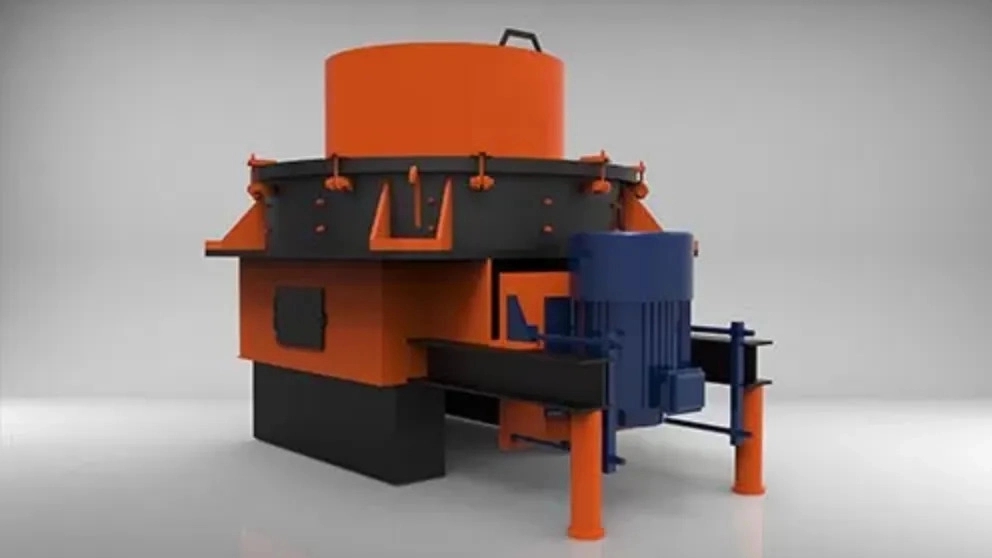

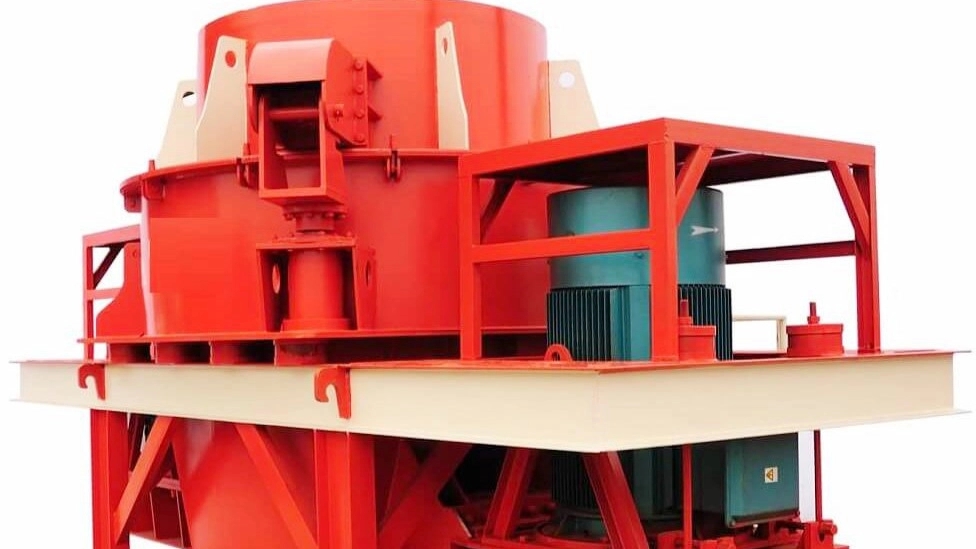

Rock and Rock Crusher

Rock and Rock crusher is a type of impact crusher. Impact crushers are available in two types, vertical and horizontal, and this device is a vertical impact crusher. In this model of impact crushers, the rotor plays an important role in creating centrifugal force and thus the crushing process. In this type of stone crushers, crushing is done using impact force. Rock and Rock crusher is a type of self-crushing sand maker. In this model of sand makers, pieces of rocks break and turn into sand due to hitting each other at high speed. Rock and Rock crusher has a high capacity for production and this feature makes this model of stone crushers unique and therefore they are famous in the industry. Because this device is a type of secondary stone crusher, it is used for crushing small pieces of stone and is not suitable for large rubble. Rock and Rock crusher is one of the most important and widely used devices for sand and asphalt factories. Also, rock and rock crusher has the best performance among similar models.

Rock and Rock crusher is used to crush materials and materials and small grains with a diameter between 6 and 30 mm. This means that this device is suitable for crushing small pieces of stones and it is not suitable for crushing large pieces of stones and rubble. The product of this machine will have a diameter between 0 and 6 mm and can ideally produce between 26 and 30 tons per hour. In the rock and rock crusher, the hammers that are rotating at high speed around the vertical axis hit the materials and cause them to be crushed. In fact, this rotation causes centrifugal force. Due to this constant rotation and incoming forces, the type of material of each of these parts is important. All these internal hammers are made of tungsten carbide, but the rotor, which is the most vital and important part of this device, is made of Hardox 400, which is anti-wear.

Functional features

A simple structure, unique performance, suitable for crushing hard rock.

Low energy consumption, high performance, high crushing ratio of the crusher, generally 10-20, up to 50-60.

With the forming function, the product is cube-shaped, high packing density, adjustable discharge size, the breaking process is simple. increased.

The use of impact breaking equipment is made of new wear-resistant materials and made of manganese steel, so the plate hammer, impact plate and lining plate have a longer life.

Easy to use and maintain, it can be used as the crusher of choice.

Unique impact cover plate crusher parts, especially for crushing hard rock, high efficiency and energy saving.