Installation support refers to all the equipment that is used to pass and maintain the equipment and facilities of the structure. In many cases, instead of using the term installation support, terms such as pipe support, installation pipe support, etc. may be used. Although these terms convey the same concept in a way, pipe supports are considered a subset of utility supports, which has become popular due to the fact that a high percentage of utility supports are used for the passage of pipes. .

Support features of the facility

1- High reliability

Prefabricated parts and benefit from the quality control of a reputable manufacturer

Existence of engineering services in the field of design, consulting and Training

reduction of human error by reducing the volume of construction operations and not requiring skilled labor

2-high execution speed

complete removal of operations Welding

Low weight of parts and quick and simple connection mechanism and adjustment of parts to each other

Presence of bean-shaped holes with appropriate length on the profile (no need for drilling) The profile and connections are galvanized

3- High flexibility and significant reduction of waste due to the existence of profiles with various sections and types of connections and the ability to disassemble and reuse and the possibility of implementing changes at each stage of the work.< /b>

4- Corrosion resistance due to the complete elimination of welding operations and the existence of various coatings such as: cold galvanized, hot galvanized.

5-Sleek and beautiful appearance and very suitable for applications that are visible.

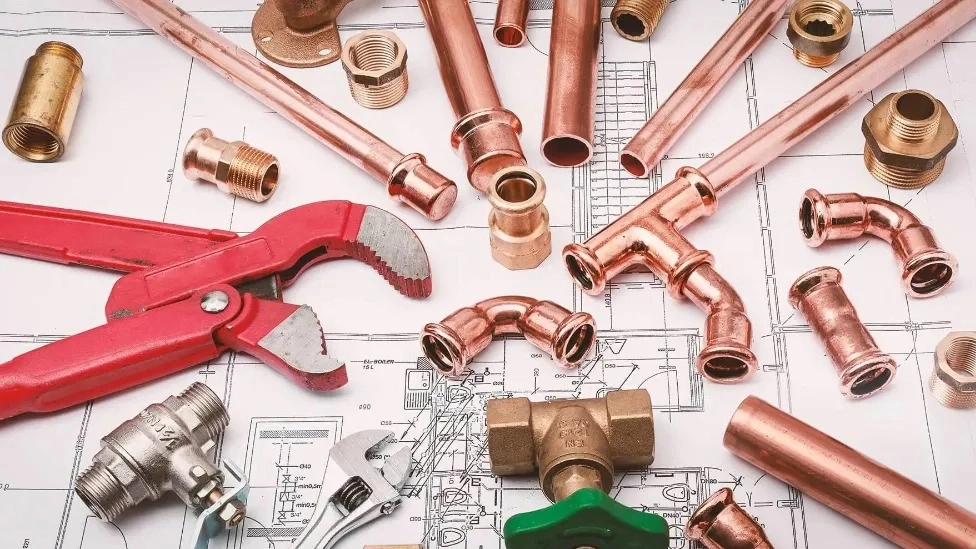

Instruction supports are actually equipment that is used to install and maintain mechanical and electrical installations, including ventilation systems, pipes smoke transmissions, cable trays, hot and drinking water pipes, building sewage, solar panels, false ceiling, fire fighting and fire extinguishing pipes, risers, etc. They are used in small and large construction projects and industrial factories.

Types of Installation Support:

HVAC System Support System:

Suitable support for installing and maintaining the air conditioning system according to the type of ventilation system, estimating the dimensions and weight of the desired equipment and Considering the implementation details of the channel system is chosen. In this regard, the functional and dimensional nature of the ventilation system is very effective in determining how to install the support.

Light-duty system support system:

Light load systems are designed for delicate installations, with low weight. The use of this level of the installation support system is for piping, ducting, wire and cable laying on the tray, but the ability to maintain and bear the load of ventilation channels and smoke transfer pipes with fine thicknesses with low and medium width, the system They have water transmission, fire fighting pipes, as well as electrical and lighting facilities. Medium-duty support system:

Medium load systems are one of the most widely used types of supports designed for medium and relatively heavy loads. The basic design of this type is for firefighting pipes and smoke transmission channels as well as air conditioning, which have different thicknesses and medium and large widths. duty system):

High weight facilities have more special conditions than other types of facilities, that's why strong and strong installation systems should be used to carry the weight of this category for high reliability.