In the category of getting to know industrial gearboxes, these parts are introduced as devices or parts for energy conversion and power transmission. In these parts, the transmission of mechanical power takes place from the producer source (engine) to the consumer (device). In this way, the required speed and torque of the consumer source are provided. For the useful operation of these parts in industrial devices, attention should be paid to the required torque of the device.

Gearboxes can be defined as parts for synchronizing the speed and torque between the two engine sources and the device in question. Power transmission in industrial gearboxes is done through a shaft. The power produced in the engine must be transmitted in the form of torque in the input shaft of the gearboxes. The required power of industrial gearboxes can be produced using different devices. Electric motors, gas, gasoline and diesel engines, all types of turbines (gas, wind, water) and solar power generation sources are among these devices. The components of gearboxes are:

- چرخ دندهها

- پوسته گیربکس

- شافت ورودی و خروجی

- بلبرینگ

- کاسه نمد

Types of industrial gearbox

One of the other important categories in the field of familiarity with industrial gearboxes is the examination of its types. According to the type of device and the defined expectations of this part, different types of industrial gearboxes are introduced. Therefore, it is better to get familiar with the types of industrial gearboxes first of all. The function of the reducer type of these parts is to increase the output torque and decrease the speed. Meanwhile, the working mode of the increasing industrial gearbox is introduced by reducing the torque and increasing the speed. Torque is the force that causes an object to rotate around an axis. In different gearboxes, this feature can be calculated using the formula for calculating the output torque of an industrial gearbox.

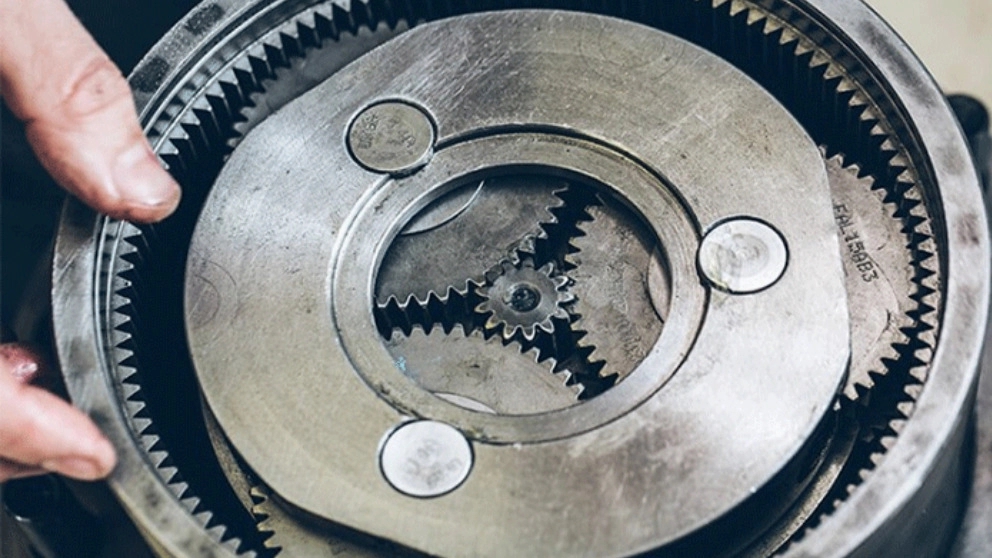

Solar gearbox

In the field of familiarization with industrial gearboxes, the name of solar gearboxes is seen more than other types of them. In these gearboxes, there is one gear in the middle and three gears around it. The middle gear is called the sun and the three around it are called the planets. To get the best performance in the solar gearbox, features such as electric motor power, output speed and number of teeth should be taken into consideration. In this connection, the input and output power of the gearbox are also important parameters that can be measured and evaluated using the gearbox power calculation formula. Solar gearboxes are among the most widely used types of these industrial parts. One of the advantages of this type of gearbox is their usability at high speeds and powers. The efficiency, power and high precision, strength and durability of solar gearboxes are other advantages of this group. By using this type of gearboxes in industrial machines, their useful life increases.

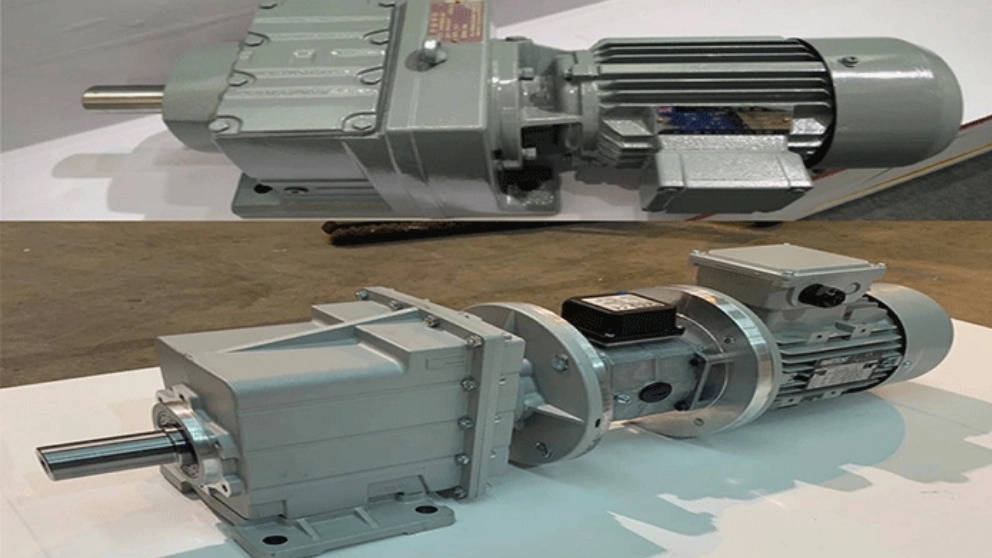

Reduced coil gearbox

These types of gearboxes are named as such because of the use of a helical gear with a large diameter. The rotary movement of the helical part acts as a driving factor for another gear or other driving parts. The main application of these gearboxes is defined in heavy industries such as chemicals, minerals and fertilizer production. According to the different conversion ratio of this group, it is necessary to select and buy them according to the needs of the device.

Helical gearbox

In the field of familiarization with industrial gearboxes, the helical type is considered very popular for many industrialists. In helical gearboxes, the gears are arranged in a spiral. How the industrial helical gearbox works is to increase the torque in the output part with the increase in speed. Small size, low power consumption, small volume and low noise pollution are among the positive features of helical gearboxes. In addition, the service life of this group of gearboxes ranks high due to the low wear of the gears. The helical gearbox can be fixed at a certain angle. so that the movement of its teeth is possible uniformly and in a fixed direction. This uniform movement can be repeated for a certain period of time. The applications of this group of gearboxes are:

- کارخانههای تولید سیمان

- کارخانههای سنگ شکن

- صنایع تولید لاستیک

- پلاستیک سازی