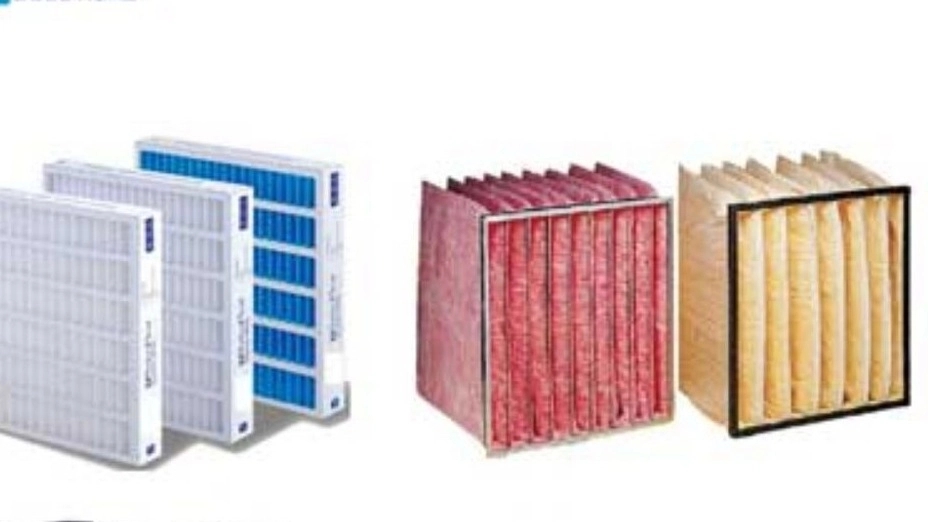

What is an industrial filter?

An industrial filter is one of the equipments whose task is to prevent the movement of suspended solid particles in fluids such as liquids or gases. In general, the filters that are used in industries perform the act of purifying fluids in two ways. Some filters perform fluid purification when the fluid is moving in and out. But there are other types of filters that perform the purification process if the fluid flow is interrupted.

What is the prominent feature of the industrial filter?

In general, the industrial filter is made of various parts. Filters must be designed and built in such a way that in addition to preventing the passage of solid materials in the fluid, they can also purify the remaining solution.

What are the characteristics of an appropriate industrial filter?

🔰 separation of solids from liquids

As mentioned, a suitable industrial filter should be able to separate the solid part of the fluid. Mainly because the membrane part and the shell of the filters are in direct contact, they must be designed to do this well.

🔰 non -obstruction

In some filters, during the separation of solid materials, the fluid and solution passage holes are closed and somehow these filters prevent the passage of fluid. Therefore, a suitable filter should be designed in such a way that it does not get blocked quickly during the separation of the solid part from the fluid part.

🔰 Possibility of draining and cleaning

If permanent filters are used in the industry, the shell of this filter should be designed in such a way as to provide the possibility of cleaning the mold.