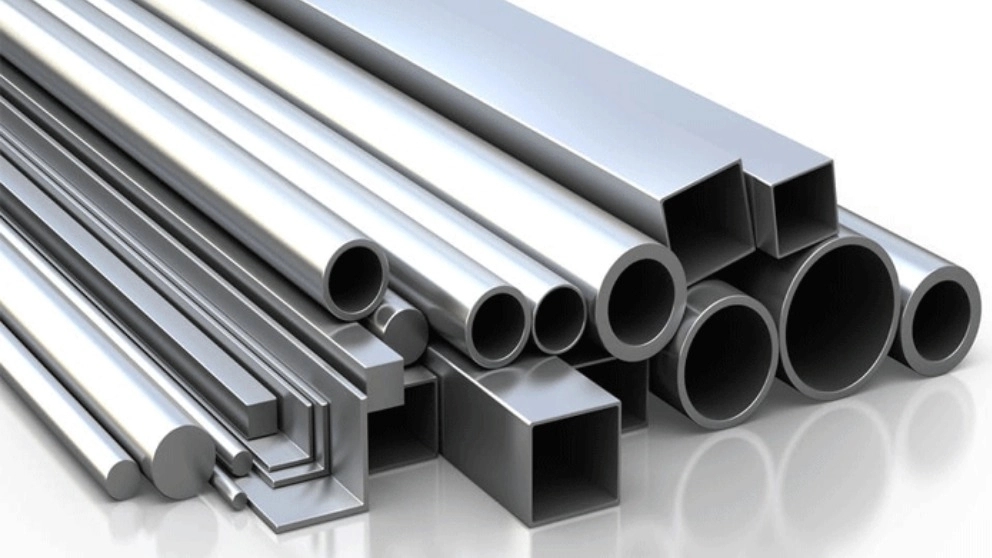

Nimonic Sheet or Super Alloys

Nimonic sheet or superalloys are alloys that have several main characteristics, including: excellent mechanical strength, resistance to thermal deformations, good surface stability and strength, and resistance to corrosion and oxidation. The crystal structure of superalloy steels is usually cubic austenitic. Examples of such alloys are: Hastelloy, Inconel, Vaspoli, René alloys, Incoloy and CMSX single crystal alloys.

Corrosion resistance of superalloy steel is widely considered in environments with the possibility of severe corrosion where heat resistance and high resistance on the integrity of the final product are important. Chemical and petrochemical processing, power plants and oil and gas industries widely use superalloys.

The oxidation or corrosion resistance properties of superalloys are created by elements such as aluminum and chromium. Also, the wear resistance increases with the presence of the carbon element. Since superalloys are intended to work at high temperatures (such as not deforming at temperatures close to melting), their creep and oxidation resistance are very important.

Superalloy steels rely heavily on both chemical and manufacturing process innovation. In general, superalloy steel can be divided into two different categories: The first category is the production process, which is about how superalloys are produced. In this category, superalloys are divided into two groups: usable and casting. And the second classification is based on the chemical composition of superalloys, which in this view superalloys are divided into three basic categories of nickel, iron and cobalt.

Nimonic Sheets or Super Alloys

🔰 Chemical and petrochemical industries 🔰 Nuclear reactors Heat exchanger tube 🔰 Industrial turbines 🔰 Marine industries 🔰 Aerospace industries 🔰 Medical parts