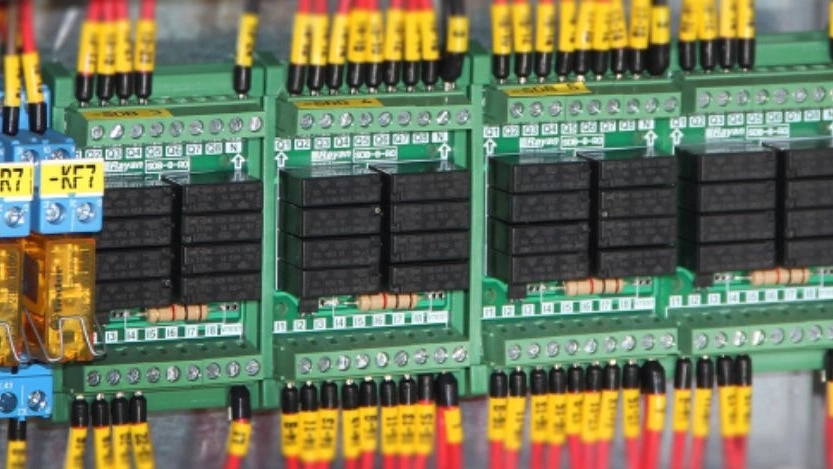

Industrial automation using electronic boards

In today's world, industrial automation is used as a key element in improving the efficiency of companies and factories. In industrial automation, the use of electronic boards is used as a powerful tool to create huge changes in companies. Basically, electronic boards play a main and vital role in industrial automation tools and devices. In this article, we will examine the benefits, features, steps of use and the meaning and concept of industrial automation using electronic boards.

Industrial automation means the use of automatic systems to control and monitor production processes in order to increase efficiency, quality and safety. Electronic boards play the role of the mastermind of these automatic systems. They perform various tasks automatically by receiving information from sensors, processing them and sending commands to equipment. This process of receiving information, processing and sending it to various equipments that is done by electronic boards is called industrial automation. Today, most companies and large factories use the systems and equipment of this automation to increase the productivity of the forces and the overall efficiency of the company.

The benefits of industrial automation using electronic boards

Using automation systems for companies has advantages that knowing these advantages can help our view of industrial automation. In the following, we will examine and explain the benefits of using industrial automation for businesses.

Increasing production efficiency

One of the things that this automation does for businesses is to reduce or eliminate human intervention from processes that can be done using automatic systems and devices. By eliminating human intervention in production processes and replacing it with automatic systems, the speed and accuracy of production increases significantly. Also, human errors that may occur in the production process are minimized and product quality is improved.

Reduce costs

Another advantage of using industrial automation is the reduction of costs caused by non-automatic production systems and human errors for business. In this automation, by eliminating waste and human errors, production costs are significantly reduced, and this issue has made the use of modern automation extremely popular.

Increase the quality of products

As we said, by using industrial automation in modern systems, automatic devices replace systems and devices based on human power. These automatic systems, with their high precision and elegance, produce quality products without defects and in general significantly increase the quality of the produced products.

Safety promotion

One of the things that is taken into consideration in workshops, companies and factories is the security of human resources, which is very important. This issue is minimized in businesses that use industrial automation. By eliminating human risks, industrial automation provides a safer work environment for employees, and the automatic systems of this automation also take into account special considerations to ensure the safety of employees.

Flexibility

Data collection and analysis

One of the things that is important in businesses is to apply changes according to the information that has existed in the business so far. Industrial automation systems using electronic boards can collect and analyze data related to the production process, which helps to improve system performance and efficiency.