Production and processing of polyethylene granules in the Kamash manufacturing group is one of the most important and specialized areas of the polymer industry in Mazandaran. Kamash Company has a great contribution to the supply of quality polyethylene granules in the country with the use of up -to -date technology, specialized manpower and world standards. Below you will be introduced to the steps, benefits and features of the production and processing of polyethylene granules in the Kamash manufacturing group.

The importance of granules of polyethylene in the plastics industry

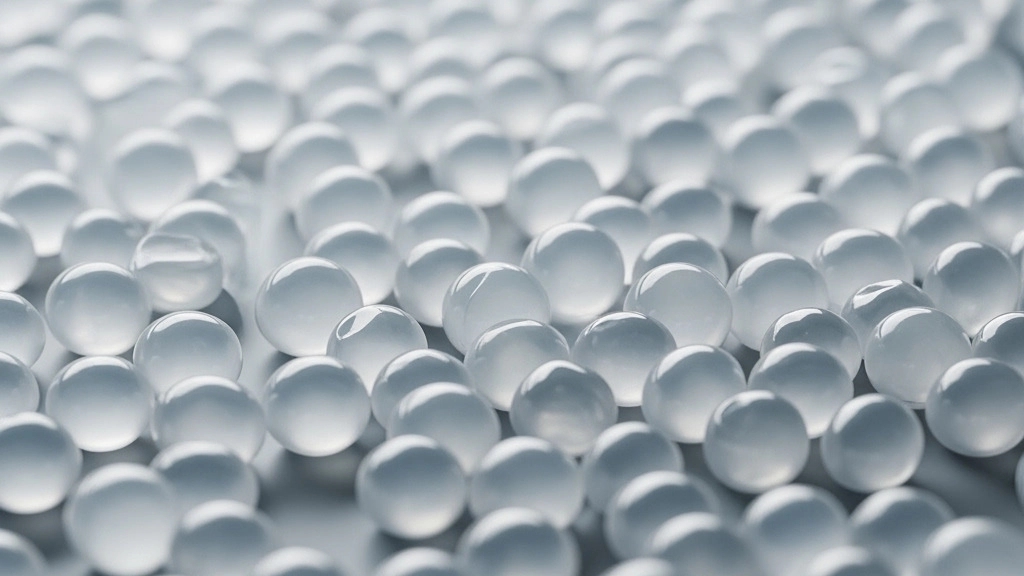

Polyethylene granule is a raw material for the production of many plastic products. Granule quality plays a direct role in the final quality of the products and enhances the durability, durability and appearance of plastic products. The production and processing of polyethylene granules in the Kamash manufacturing group, with special attention to this importance, has always emphasized the improving standards and satisfaction of downstream industries.

Polyethylene granular production and processing process in Kamash manufacturing group

Selection of raw materials

The first step in the production and processing of polyethylene granules in the Kamash manufacturing group is the selection of high quality and standard raw materials. Proper raw materials will guarantee a flawless process and produce granules with desirable properties.

Melting and extrusion

Cutting and cooling of polyethylene strands

After the strings are removed from the extruder, these strands are converted into small granular pieces. The cooling of these granules is immediately and in principle to maintain the physical and chemical quality of polyethylene granules.

Drying and packaging

Benefits of Polyethylene Granular Production and Processing in Kamash Manufacturing Group

The use of the technology of the day

The Kamash manufacturing team always uses the latest equipment and technologies to minimize the amount of raw material loss in addition to enhancing the quality of polyethylene granules.

Multi -step quality control

One of the prominent features of the production and processing of polyethylene granules in the Kamash manufacturing group is the existence of multiple steps of quality control during and end production. This precise control ensures the physical, mechanical and chemical properties of the granule.

Responding to market need

Due to the increasing demand for polymer and plastic products, the supply of high -quality polyethylene granules is of great importance for industry activists. The Kamash manufacturing team with high production capacity and rapid accountability has eliminated the concerns of downstream industries.

Different applications of polyethylene granules production

Granules produced in the production and processing of polyethylene granules are used in the Kamash manufacturing group in various industries including film and nylon production, injectable parts, food packaging, pipeline, toys and automotive parts. The uniform quality and mechanical properties of these granules have made them popular in various industries.

Features of high -quality polyethylene granule

In the process of producing and processing polyethylene granules in the Kamash manufacturing group, observance of the following criteria guarantees the superior quality of products:

Color and transparency

Granule must be transparent and uniform, indicating the purity of raw materials and standard production.

Absence of impurities

Granules produced by the Kamash production group are free of any impurities so that the final product is flawless.

Proper mechanical properties

Strength, flexibility and melting point are important features of granules that are carefully controlled in the production of the Kamash production group.

Conclusion

In this article we have thoroughly examined the production and processing of polyethylene granules in the Kamash manufacturing group and explained the benefits, production steps, features and applications. The selection of a valid and experienced supplier such as Kamash Manufacturing Group in Mazandaran is an important step in improving the final quality of polymer products in various industries. If you are looking for the best polyethylene granules for your business, the Kamash manufacturing team will be the best choice.